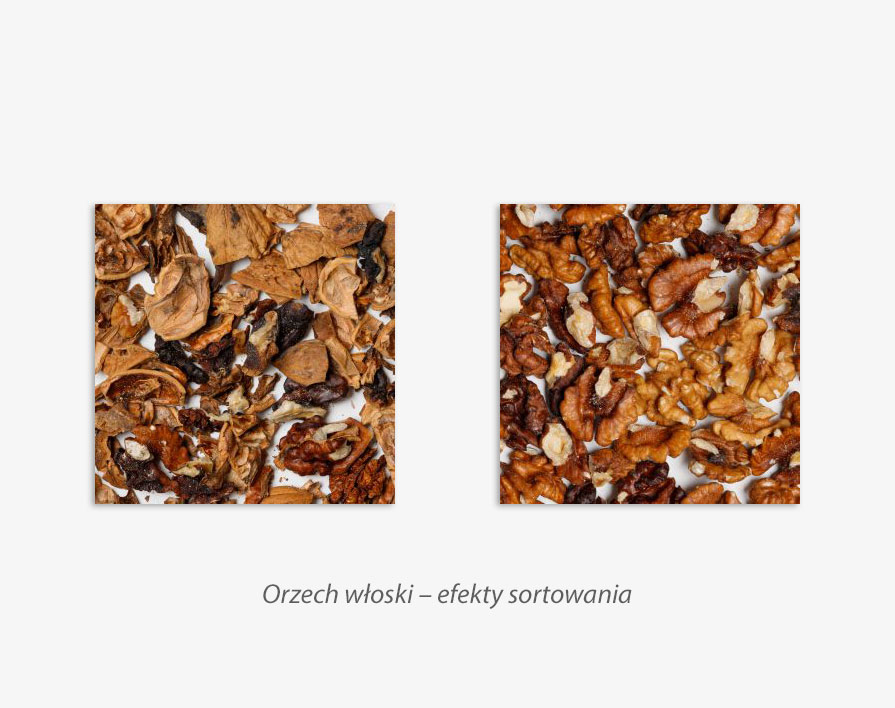

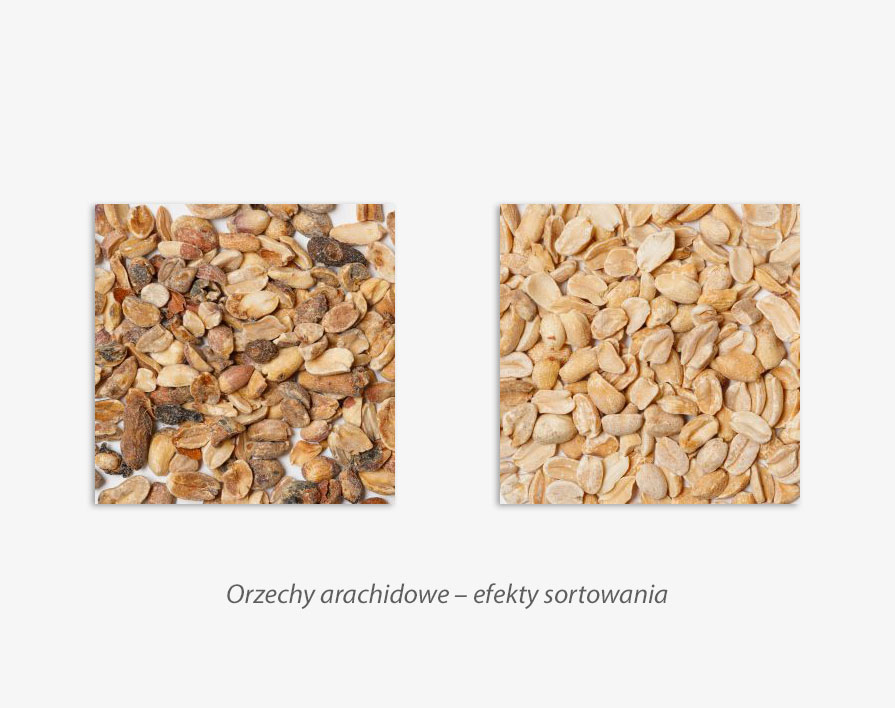

Sorting of nuts

Sorting of delicacies and, above all, nuts and almonds susceptible to chipping has never been so efficient and safe for the cleaned assortment, while also maintaining high process efficiency.

Product safety

Clever design of the SmartSort solutions for nut sorting reduces mechanical damage by reducing the time in free flight of the assortment and limiting collisions with other nuts and elements of the device, which is particularly important with valuable for fragile assortments.

Most accurate optical sorting

Cloud colour cameras provide the highest level of sorting, without compromising quality, and the EagleEye software running on proprietary integrated circuit system can detect up to 7 different defects in a single cleaning process.

Energy efficient LED strips provide optimum illumination of the assortment and the background, which assists in the work of colour cameras.

SmartSort smart sorter algorithms not only detect colour defects but also those of shape and size, ensuring the highest quality where there is a variety of contaminants.

SmartSort sorters can be equipped with an additional set of InGaAs cameras developed according to our own patent, specifically for sorting applications that allow the detection of an additional group of defects based on an imperceptible physical characteristics of the material, supporting colour cameras when removing shells and other foreign bodies.

Maximum yield, minimum loss

The solenoid pneumatic valves of our own design, with the highest available intervention frequency, provide short precision compressed air shots, minimizing the loss of good material.

The special two-level belt SmartSort model has an internal material feed system from behind – allowing re-sorting without additional peripheral devices.