Groats cleaning

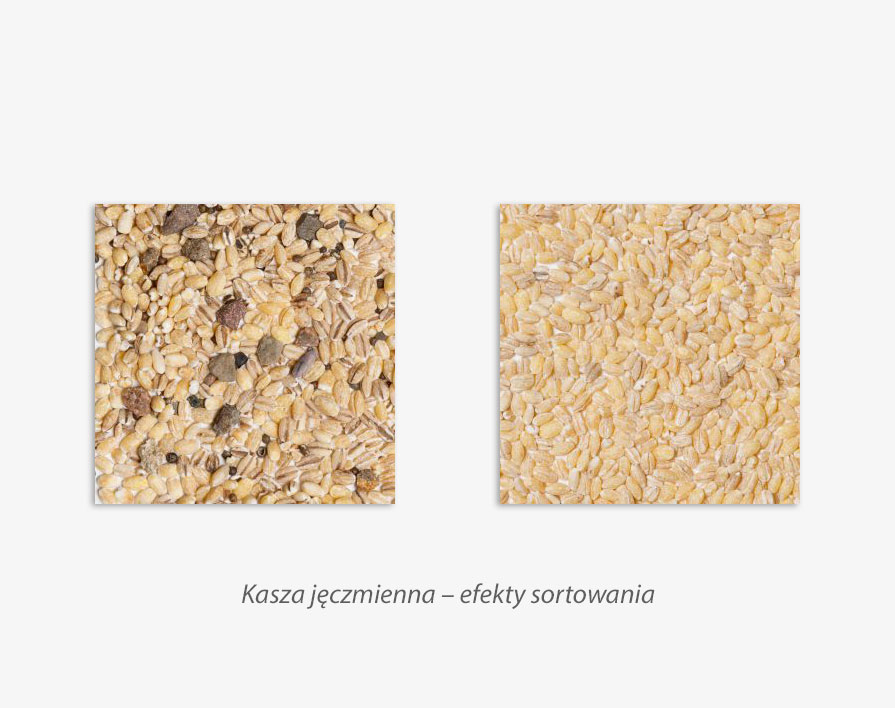

SmartSort offers solutions that are exceptionally well suited for sorting and cleaning of groats and removal of contaminants found in the assortment of this type.

Individual approach

The highest resolution full-colour Cloud cameras provide highest quality cleaning of all kinds of groats, without compromising quality – leaving no extraneous seeds in the finished assortment. EagleEye programming allows to set up to 7 different contaminant removal criteria in a single process.

The InGaAs near-infrared technology allows for the removal of contaminants such as wild millet from lamb groats, as well as some organic or inorganic contaminants that have gotten mixed into the assortment most often at harvest stage.

Adaptable and adjustable nozzle size allows working with both fine lamb groats and larger assortments of buckwheat and swell. The practically limitless options of the device for saving programs allow for easy reprogramming of the SmartSort devices for other sorting tasks.

Small- and large-scale production

SmartSort Optical sorters are available in any gutter configurations – from 1 to 10 gutters – with the option to separately program each gutter, making them the most flexible devices on the market that can be adapted to both small enterprises as well as mass production.

High-frequency electromagnetic solenoid valves and a unique material feeding system make even the smallest device achieve high performance, and the largest ten-gutter models offer the largest throughput available on the market.

Consistent performance and malfunction prevention

Automatic brushes and wipers, as well as smart-positioned aspiration connections ensure a consistent high quality of the sorter's work, thanks to good visibility for cameras even with high dust contamination of the assortment.

The solenoid valves of the ejection zone are additionally protected against moisture and oil contamination, with sets of different sizes – depending on the device’s air intake.

Low labour and maintenance costs

Optimised demand for compressed air and low demand for electricity, customizable on demand even for power consumption from low-voltage networks, ensures that the machine's operating costs are minimal, thus increasing cleaning benefits.

Individual service parts of the device need to be replaced no sooner than after half a year of machine use.