Other cleaning devices and technological lines for agriculture

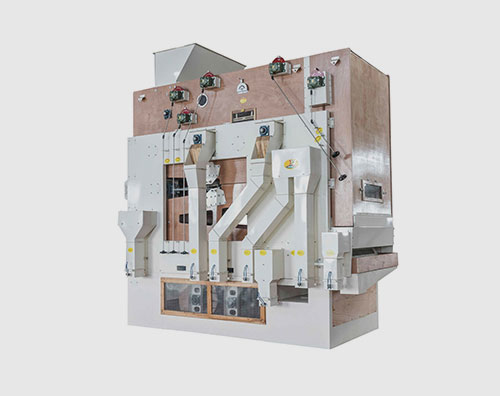

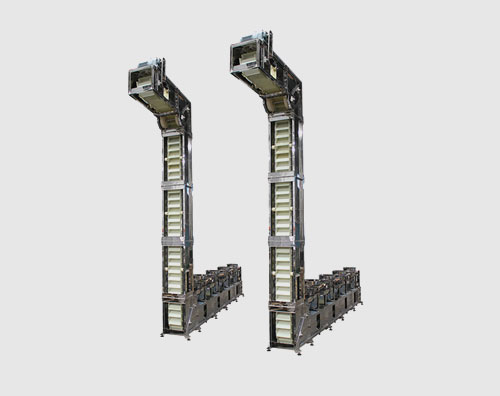

Comprehensive optimization of sorting processes requires the delivery of properly prepared material to the optical sorter. When the customer acquires or produces material that requires prior cleaning or separation steps before entering the optical sorter, we can implement appropriately selected cleaners, cylinder separators, gravity tables or other devices according to the same optimization criteria.

At each stage, the goal of our activities is to obtain the maximum ratio of processed or cleaned material to the waste from this process, so that nothing is unnecessarily lost in the material batch. In addition, we can make plant designs from scratch, built with a perspective f later supplementing them with further process steps and at the same time in accordance with our principles of optimization.